-

Milestones

Year

-

Appointment of Authorized distributor for Honda Co-branded batteries in Nepal

July, 2022

-

After-Market Tie-Up Agreement with TATA Motors – CVBU

July, 2022

-

New Maruti Celerio CNG is now powered by Tata Green Batteries

Mar, 2022

-

Tata Green Batteries launches 70D23L-BH aimed at catering to the Hyundai Creta, Verna, i20 - diesel applications

Dec, 2021

-

Tata Auto Comp GY Batteries has been awarded the prestigious Purchase Order from South Bengal Roadways, for supply of CV batteries for their Bus fleet

Sept, 2021

-

Tata Green Batteries launches GYZ20L, a powerful VRLA battery for the premium motorcycles of Honda and Harley Davidson

July, 2021

-

Tata Green Batteries launches the power packed YTZ10S, an original VRLA 2W battery for high end bikes above 300cc

July, 2021

-

Tata Green Batteries has achieved the title of "Emerging Industry Leader" in the Tata Business Excellence Model (TBEM) assessment

May, 2021

-

Tata Green Batteries launches YTZ7-H Honda co-branded battery for BS-VI 350cc application

Mar, 2021

-

Tata Green Batteries along with Independent After Market are one of the main Event Sponsors for CII Autoserve 2020, which is India's Go to Event for Automotive Aftermarket

Nov, 2020

-

Tata AutoComp GY Batteries has been awarded the prestigious Purchase Order from Himachal Road Transport Corporation Shimla, for supply of CV batteries for their Bus fleet

Nov, 2020

-

Tata Green Batteries (TGY) bags the prestigious order of Jawa Motorcycle from Mahindra & Mahindra, the owners of Jawa brand in India

Oct, 2020

-

Tata Green Batteries launches its first DVC Digital Video commercial – #MainFarkNahiKarta in Social media platforms which gets tremendous response with over 1.5 Mn views

Oct, 2020

-

Tata AutoComp GY Batteries has been awarded the prestigious business from Perfect House Pvt Ltd, Satara for supply of power back-up batteries for their Gensets

Oct, 2020

-

Tata AutoComp celebrated 25th Silver Jubilee on complete 25 years on 17th October 2020

Oct, 2020

-

Honda Motorcycle and Scooters India (HMSI) reinforces its trust in Tata Green Batteries for its latest offering -The Honda H’ness CB350 Motorcycle

Sept, 2020

-

TATA Green Batteries (TGY) bagged LOI from India Yamaha Motor Pvt. Ltd for supplying batteries to new FZ series motorcycles (BSVI complaint)

Sept, 2020

-

Tata Green Batteries Launches Paperless warranty facility – a smart and convenient way to get your warranty without any paperwork – access from anywhere in India

July, 2020

-

Launched Parivar Program for Tata Fraternity

June, 2020

-

Launched a mobile application ‘We Care…Aapke Arogya ka Saathi’ for TATA Autocomp Business Units and a Daily Health Monitoring application for employees and workers

June, 2020

-

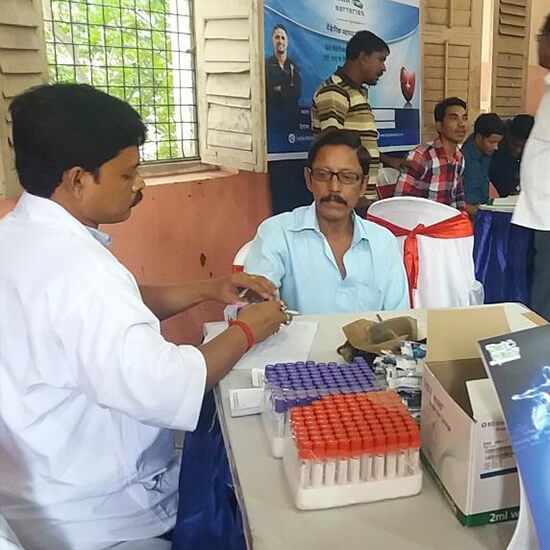

Started 'Free Battery Checkup Camp' on a society level during the COVID-19 lockdown to improve brand awareness

May, 2020

-

Launched an online training portal for ‘Product & Channel Management Module’

April, 2020

-

Conducted an ‘All India Channel Meet 2020’ in Istanbul with more than 160 channel partners from across India

Mar, 2020

-

Featured in Overdrive magazine

Mar, 2020

-

Launched TGY Buddy: An Artificial Intelligence-based chatbot to answer queries on travel policy, mediclaim insurance and grooming standards. This was the first of its kind developed in the automotive manufacturing industry.

Feb, 2020

-

Signed an aftermarket tie-up with Maruti Suzuki

Dec, 2019

-

Tata Green Batteries (TGY) has bagged an order to supply batteries for the recently launched Maruti Suzuki S-Presso, a BS-VI compliant SUV. The 34B19 battery powered by GS Yuasa’s World Class Ca-Ca Technology has been approved for this model

Oct, 2019

-

Tata Green Batteries has bagged an order to supply batteries for the recently launched Honda Activa 125 FI, powered by BS-VI compliant motor.

Oct, 2019

-

Captured new platform from Honda for BS VI vehicles

Oct, 2019

-

Featured in Outlook magazine, which covered the journey and future roadmap

Sept, 2019

-

Launched ‘ChannelKonnect’ application for distribution and channel management

Aug, 2019

-

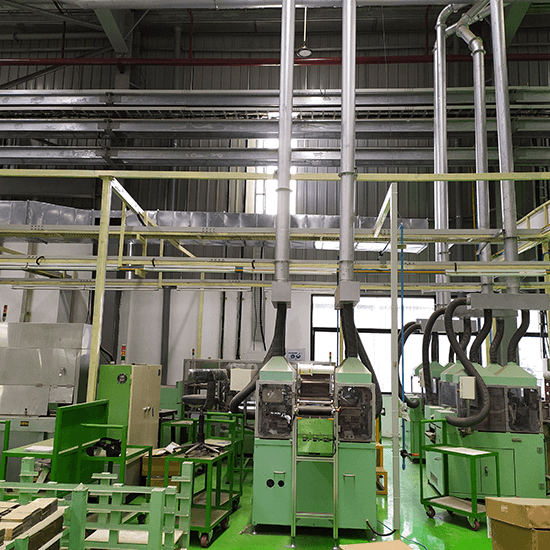

Started operating with three lines of two-wheeler batteries

July, 2019

-

Achieved highest ever score for employee engagement, which was significantly higher than our competition and prior benchmarks

July, 2019

-

Implemented Out of Home (OOH) media advertising campaign at Delhi and Mumbai international and domestic airports

July, 2019

-

Covered under ‘Inspirational Brands: Make in India’ series launched by CNBC

June, 2019

-

Implemented TV campaign that established Tata Green Batteries as 'India Ki Battery' on major news channels during Election Exit Polls and Election Results

May, 2019

-

Launch of flat-plate E-rickshaw `Sawaar-E` batteries in 100 ah and 120 ah capacities

Jan, 2019

-

Reached out to 14 million happy customers

Jan, 2018

-

Received the first ever 5-star rating in the BSC audit

Dec, 2017

-

In-stadium advertisement during the Australia and New Zealand home cricket series

Nov, 2017

-

Launched ROADSTAR range of commercial vehicle batteries that promised a new look and feel

Aug, 2017

-

Started supplying two-wheeler batteries to Piaggio in their Baramati plant

Aug, 2017

-

Launch of new Premio PC / UV range with advanced features

June, 2017

-

Launch of 2.5 ah, 7 ah and 9 ah two-wheeler VRLA batteries

June, 2017

-

Launch of Jeevan batteries with industry-first warranty proposition

May, 2017

-

Tata Green Batteries and HMSI sign an aftermarket tie-up and launch YTZ-4H (Honda co-branded) battery

May, 2017

-

Tata Green Batteries Connect App - Mobile application launched for `Warranty and Complaint Management`

April, 2017

-

Introduction of new in-house-produced variant YTZ5 (4 ah)

Feb, 2016

-

Entered into an aftermarket agreement with KOEL

Jan, 2016

-

Start of Production (SOP) for two-wheeler manufacturing in Line 2

Aug, 2016

-

Began supplying two-wheeler VRLA batteries to 4th HMSI (Honda Motorcycles and Scooters India) plant in Gujarat

May, 2016

-

Touched 7 million happy customers

April, 2016

-

TATA AutoComps System Ltd. wins Best Employer Award

April, 2016

-

Began in-house production of two-wheeler VRLA batteries – YTZ4 (3 ah) & YT5A (5 ah)

May, 2015

-

National Channel and Sales conference held in Abu Dhabi

Dec, 2014

-

Parivaar Program launched exclusively for Tata Group employees

Sept, 2013

-

Launch of modified Gold XT battery range for PC segment

Sept, 2013

-

Retail base touches 5000

Aug, 2013

-

Launch of battery for Hyundai i10

Aug, 2013

-

Started OEM supply to Maruti Suzuki India Ltd.

Aug, 2013

-

Launch of 1000th brand value store in Mumbai

July, 2013

-

Started OEM supply to JCB

July, 2013

-

Touched 5 million happy customers

July, 2013

-

Launch of improved HD battery range for commercial vehicles and inverters

April, 2013

-

Launch of Silver XT range of batteries for PC segment

Sept, 2012

-

Launch of Velocity+ range for two-wheelers

July, 2012

-

Gained 3 million happy customers

Mar, 2011

-

Started OEM supply to Toyota Kirloskar Motors Ltd.

Oct, 2010

-

Launch of Velocity range for two-wheelers

Sept, 2010

-

Started OEM supply to Kirloskar Oil Engines

May, 2010

-

Gained 1 million happy customers

Mar, 2010

-

Launch of Silver Plus range in PC / UV segment

Mar, 2010

-

Voted the third best battery brand by "Electronics for You"

June, 2009

-

Started OEM supply to Nano

Nov, 2008

-

Launch of commercial vehicle batteries

Feb, 2008

-

Launch of inverter batteries

Jan, 2008

-

Launch of tractor batteries

Dec, 2007

-

Began customer care toll-free service

Dec, 2007

-

Achieved pan-India channel presence

Aug, 2007

-

Launch of two-wheeler batteries

June, 2007

-

Launch of PC / UV batteries

Feb, 2006

-

Production commences

Dec, 2006

-

Birth of the brand

Nov, 2006

-

Establishment of Tata Green Batteries

Oct, 2005